The Indian Corps and the Introduction of Trench Mortars. November 1914. (Chap.1 Pt.3)

Trench Mortars.

The BEF of 1914 was not ignorant about trench mortars or their capabilities. Military observers had seen them in action during the Russio-Japanese War, but the army lacked practical experience in their use for their training focused on mobile warfare against a modern European army that did not visualise a demand for the weapons of static warfare such as the grenade and trench mortar. There were some officers who went to France with the BEF who were aware of the potential usefulness of trench mortars. Lieut.-Colonel C.S. Wilson, Commander Royal Engineers, 3rd Division, had a long-standing interest in trench mortars, having constructed examples on the Japanese pattern during the annual Royal Engineer Field Days when the Field Companies showed off their skills and inventiveness. Wilson’s most successful mortar fired a 6 lb bomb over 600 yards with commendable accuracy. Drawing upon the 3rd Division’s experiences of trench fighting on the Aisner, at Neuve Chappelle during the battle of La Bassée in October, Wilson, composed a memorandum to the Chief Engineer II Corps suggesting the provision of trench mortars.[1]

Despite his interest in trench mortars Wilson was not responsible for introducing them to the BEF. This is surprising for his Field Companies probably produced the first extemporised hand grenade used in action by the BEF so why they did not turn their attention to producing a trench mortar? There are two possibilities. Between September and late November 1914, the 3rd Division was continually in action so its Field Companies would have had neither the men, nor time, to manufacture and test a trench mortar. Secondly, Wilson had fixed ideas about how to make an extemporised mortar. In his view it must be made of cast iron, 4 to 5 inches in diameter, about 15 inches long, with one end sealed off with a screw cap similar to the pipes used in water supplies and thick enough to withstand the force of the discharge. Believing that he would eventually find the right materials he scoured every town the Division passed through, but found nothing suitable and, unwilling to change his preconceived views, 3rd Division were not the first to produce a functional trench mortar, that accolade was to go to the Sappers and Miners of the Indian Corps.

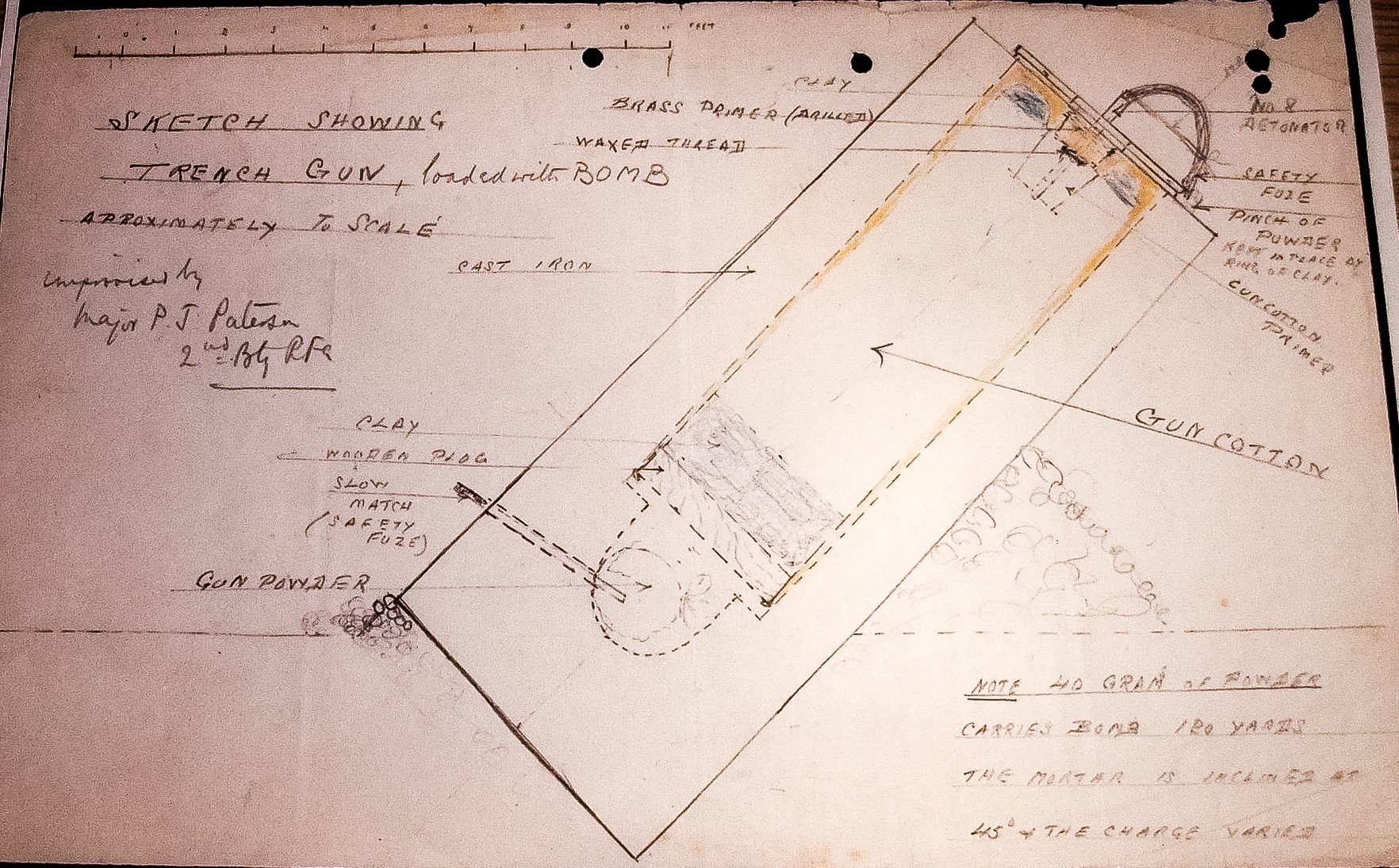

The development and manufacture of trench mortars by Woolwich Arsenal and the Trench Warfare Department are dealt with later. This section will focus on the development of the light trench mortar by the Sappers and Miners of the Meerut Division. The catalyst for this event was Major P.J. Paterson, 2nd Battery Royal Field Artillery, attached to the Meerut Division, who, sometime during the first week in November, approached No 4 Company, King George's Own Sappers and Miners to enlist

[1] TNA: WO95/1697: 3rd Division, War Diary, November 1914. Appendix L

Major Paterson’s Bomb Gun. TNA: WO95/3937: War Diaries. Meerut Division. 13th Bde. Royal Field Artillery.

The mortar was constructed from a short length of cast-iron pipe, closed at one end, and fired with gunpowder contained in small bags made from sacking pushed down the barrel with a ramrod and fired with a short length of safety fuse pushed through a touch hole drilled close to the base of the barrel. The shells were 18-pounder brass cartridge cases with about 3 inches cut off the open end, and the brass plug on the base that held the fuze was drilled to accommodate a No. 8 detonator. When filled with high explosives and closed with a wooden lid, the shells weighed approximately 3 lb 12 oz. A short length of instantaneous fuse was attached to one end of 3 inches of slow fuse; the other end clamped onto the detonator, and the fuse was bent around the outside of the shell casing so that the instantaneous fuse was lit by the flash of the propellant just as the bomb left the barrel. The bombs did not slide down the tube, as was the case with later mortars, but rested on the mouth supported by the rim of the cartridge case. This type of ammunition was christened "Paterson's Pills for Portly Prussians." There was no supporting frame, so the mortar tube was propped up at a suitable angle with sandbags, and the range was adjusted by varying the angle or the number of small bags of gunpowder.

The first two mortars manufactured appeared to be experimental prototypes: one made from a length of iron pipe and the other from wooden staves bound with iron hoops, similar to the mortars used by the Japanese during the Russo-Japanese War. In the unit War Diaries, there are entries between November 12th and 17th concerning the development of the mortar. On the 18th, the two mortars, along with 20 rounds of ammunition, were placed in a front-line trench occupied by the Leicestershire Regiment. The next morning, Lieutenant Trevor, accompanied by an NCO and six Sappers from the 4th Field Company, became the first troops in the BEF to fire a trench mortar in anger at the enemy, landing three of the bombs on target, a particularly annoying German sap-head, much to the delight of the infantry. This first trial immediately suggested areas for improvement. The lack of a carriage to support the mortar tube impaired accuracy. The black powder should be sifted and weighed more accurately to improve consistency in range, and the sacking should be omitted, as it was blown burning from the gun, leaving a trail of smoke that disclosed the position of the mortar to enemy retaliatory fire.

The mortars were successfully deployed again on the 20th and 21st, and the wooden mortar blew up when taken out by the inexperienced Company Sergeant Major Gibbon on the 23rd. Experience and experimentation steadily improved the mortar design, including a significant advance on the 2nd December, when bombs fitted with percussion fuses were tested; however, as they are not mentioned again, we must assume this line of enquiry was abandoned because the fuses were too challenging to produce in the quantities required.

Lieutenants Trevor and Fairley of the 4th Field Company introduced what were probably the most significant innovations in trench mortar design when they unveiled their new pattern on the 26th of November, a radical departure from Major Paterson’s prototype of only a fortnight before. This was their tripod gun, which had a barrel of carefully chosen steel pipe, 75 mm in diameter, supported on tripod legs that allowed the barrel to be elevated, depressed, and traversed. The mortar tube rested on a detachable steel plate, or spade, which prevented the recoil from driving it into the ground and the gun, together with the legs which folded easily, weighed 50lbs and could be carried along a trench by one man. It fired a 4-pound bomb with great accuracy at ranges between 50 and 300 yards.

This was the model adopted for production, and six were in action with the Corps by the end of November, with ten more due for completion during the first week in December, giving a total of sixteen —two per battalion for each of the Infantry Brigades in line. The ammunition was surprisingly sophisticated, considering the Sappers and Miners were not equipped with machine tools such as lathes and other metalworking machinery. Still, it was always possible that such machine working was contracted out to local French engineering workshops. According to the War Diary, the model for their mortar bomb was a German dud. No details or diagram of this German bomb appear to exist, which is a pity, because if it were the model for the Sappers and Miners’ bomb, it suggests it was fired from an extemporised mortar rather than a regular minenwerfer that fired a sophisticated shell similar to that used by the artillery.

Mortar bomb produced by 20th Company Bombay Sappers and Miners, January 1915. WO/3919: War Diary

The bombs consisted of a tin cylinder, the top and bottom sealed with wooden plugs. Half a slab of gun cotton was carefully centred in the cylinder and packed around with a mixture of flaked gun and small pieces of iron to act as shrapnel. The top wooden plug was drilled to accommodate the detonator, and a wooden nipple was installed to retain the fuse. These bombs were capable of both destruction and anti-personnel. Accuracy and range were improved by ensuring that the cylinders were carefully made to fit snugly in the tube as they slid down to rest on the propellant.

Tactical Innovations.

The introduction of these new weapons brought about significant tactical innovations. The Indian Corps designating their light mortar as an infantry weapon, training infantry as mortar crews, the first being eight men from the 2nd Battalion, The Leicestershire Regiment (Garwhal Brigade), who were attached to the 4th Field company for instruction in the use of the bomb gun on 1 December.

With a new weapon system adding to the infantry's firepower, it was essential to develop a workable management structure to incorporate these new trench mortar crews into the chain of command. After a conference of senior officers, it was agreed that the management and coordination of the Corps' sixteen guns a new position was to be created in the chain of command, the Divisional Mortar Officer who, in turn, was supported by the two Brigade bombing officers who added the management of the eight trench mortars allocated to their Brigade to their list of responsibilities. The responsibility for overseeing the training of the mortar crews lay with the Brigade bombing officers, who had to ensure that each infantry battalion sent sufficient men to the mortar school so that each mortar was provided with four trained men: two forming the active crew and two as reserves or replacements. Under this scheme, an infantry Division could have as many as a hundred infantry trained in the use of trench mortars. Although it is unlikely that such a total was reached in practice, the fact that the requirement existed on paper reflects the Indian Corps' commitment to the new technology. To undertake this training, the Indian Corps developed the first Mortar Training School in the BEF, the firing range completed by the Sappers and Miners on 23 November 1914. When a division had completed its rotation in the trenches, the mortars and ammunition were treated as trench stores to be handed over to the Divisional Mortar Officer of the incoming Division, who would provide his own gun crews.

Sir Philip Geoffrey Twining by Bassano Ltd. whole-plate glass negative, 12 May 1919 © National Portrait Gallery, London

The individual who probably contributed most to ensuring that the BEF adopted the hand grenade and trench mortar as infantry weapons was Philip Geoffrey Twining. He was born on September 7th 1862 in Halifax, Nova Scotia. He enrolled at the Royal Military College of Canada in Kingston, Ontario from 1880 to 1883. On graduation no commissions were available is small Canadian Militia, and having to develop a profession adopted to train as a mechanical engineer. To obtain practical knowledge of his profession he took employment as a journeyman fitter in the leading railway shops in Canada and the USA.

In the autumn of 1885 Canada decided to increase the establishment of Royal Engineer officers and Twining was successful in obtaining one of the 24 Commissions. He joined the Royal Engineers at Chatham in January 1886 and, after a year’s instruction at the School of Military Engineering, he embarked for India in February 1887.

He was to spend most of his career in the Indian army where he gained valuable experience in engineering, railways, and surveying, spending 1901 in Africa surveying the railway route from the coast to Lake Victoria and later served on the British Military Mission to China after the Boxer Rebellion. In 1911, promoted to Lieutenant-Colonel, he took command of the 1st King George’s Own Sappers and Miners and in 1914 went to France as Commander, Royal Engineers to the Meerut Division. When the infantry of the Indian Corps was transferred to the Middle East at the end of 1915 he was retained to be appointed D.A. & Q.M.G. to XIII Corps and in late 1916 Eric Geddes, recently appointed by Sir Douglas Haig as Director of Military Railways and Inspector-General of Transportation, specifically ask for Twinning to be appointed Deputy Director-General of Transportation, a post he held until appointed D.A. & Q.M.G. First Army and in 1918 appointed to the most senior position in the Royal Engineers, the Director of Fortification and Works in the War Office. He died in 1920 aged 57.

Lieutenant-Colonel Twinning’s support for the development of extemporised grenades extended to carrying out his own experiments to improve functionality and safety but his most significant impact came through his organisational ability. He organised the all-important demonstration of the Sapper and Miner’s trench mortars to Sir John French and other senior commanders that kick-started the dissemination of the trench mortar technology and tactics to other Divisions in the BEF and over the succeeding weeks, orchestrating and co-ordination the demonstrations and training of the British Field Companies in the manufacture of grenades and trench mortars by the Sappers and Miners. Twinning was far ahead of other senior officers in the BEF in his appreciation that this new form of trench fighting would require a huge investment in grenades and trench mortars and became the first to establish and finance a supply chain with local French suppliers that ensured his first bomb factory at Gorre had a constant flow of locally sourced components such as timber, nails, wire, and the like, which he extended to arranging the lease and financing of the bomb factory in Bethune and became a powerful advocate in convincing GHQ to invest and support the Royal Engineers in other Divisions to set up bomb factories, arguing that the BEF must be prepared to manufacture extemporised weapons on a very large scale as long as supplies from the UK remained inadequate.

At the beginning of December 1914 GHQ finally persuaded the War Office to take a look at the locally produced extemporised grenades and trench mortars that they were finding increasingly useful in waging trench warfare against the enemy and, on 9 December, Lieutenant-Colonel P. G. Twining, Commander, Royal Engineers, Meerut Division, was recalled to London to advise the Royal Ordnance Factories, and the munitions industry generally, on the design and manufacture of trench mortars and grenades.

He naturally explained the characteristics of the Indian Corps 95-mm mortar, and this was the pattern adopted by the Chief Superintendent Ordnance Factories as the model for the Woolwich 3.7-inch Light Trench Howitzer. When Twining returned to his duties in France on December 21st, he carried with him a promise from the Chief Superintendent that Woolwich would manufacture 100 mortars and 50,000 rounds of ammunition for delivery as soon as possible and that he should expect the first trial batch to reach France within a fortnight. Surprisingly, the promise was kept, or at least the first part, and the first 20 mortars with 1,000 rounds of ammunition were sent to France on January 3rd, an indication of the cultural and procedural changes occurring in the Ordnance Board as it moved away from its traditional munition development cycle to meet the needs of the army fighting in France.